Calico Printing

COTTON PATTERNS AND HUMAN COSTS

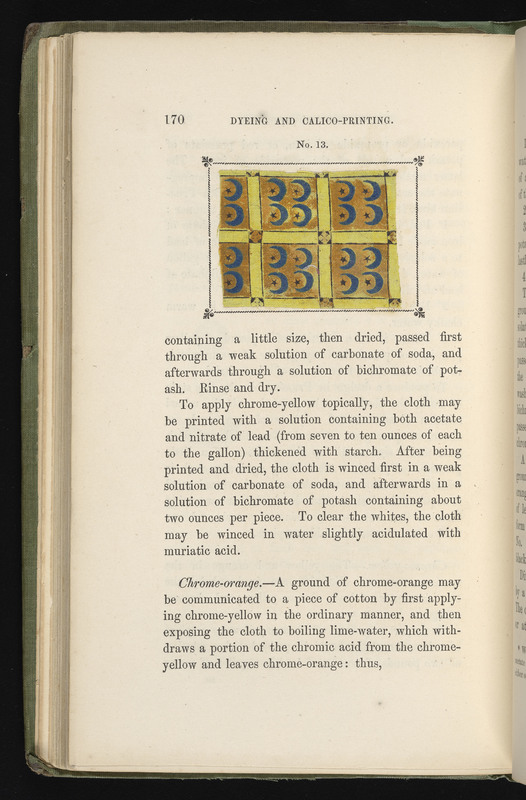

Mordant dyeing was famously developed in India, where makers of chintz painted cotton with different metallic salts (mordants) that produce different colors from a single dyebath. With industrialized calico printing—which capitalized on abundant, inexpensive cotton produced by enslaved Black people in the American South—professional chemists like Edward Parnell were increasingly hired by dye companies to devise new mordants for new color variations.

On these pages, Parnell demonstrates a method of saturating cotton fabric with lead acetate, followed by a chromium compound, to produce a yellow that can then be turned orange with lime water. Chromium and lead are exceedingly toxic, of course, and this textile would likely poison both its makers and wearers.

Parnell worked for one of the many dye factories clustered around St. Helens, England, which became notorious for its pollution. Author Robert Sherard wrote in 1897 that its factories produced "foul gasses which… rot the clothes, the teeth, and, in the end, the bodies of the workers."

— Written by Sarah K. Rich (Art History, Center for Virtual/Material Studies)

Edward Parnell

A Practical Treatise on Dyeing and Calico-printing

London: Taylor, Walton, and Maberly, 1849